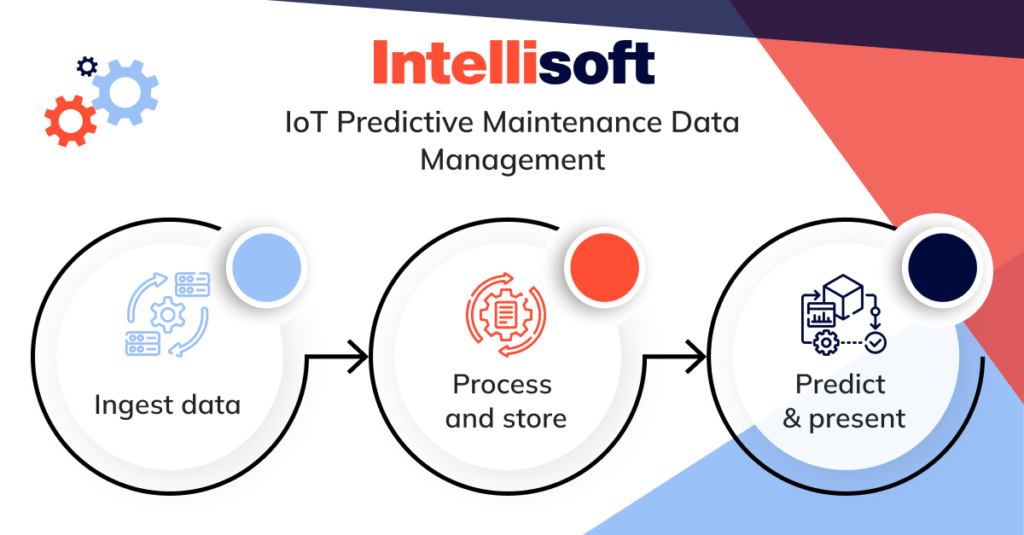

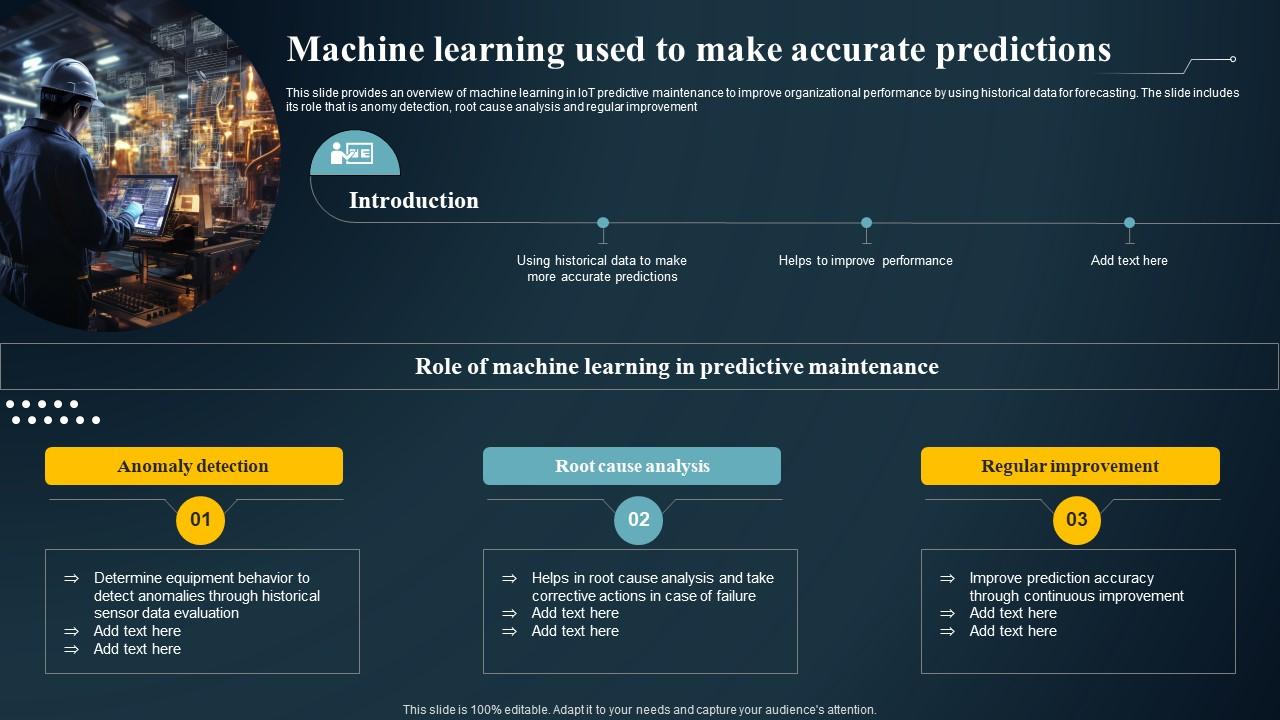

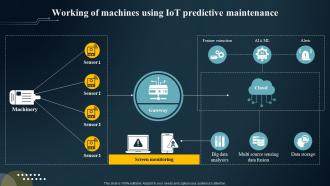

Machine Learning Used To Make Accurate IoT Predictive Maintenance Guide Circuit Diagram What is IoT Predictive Maintenance? IoT predictive maintenance is a method of predicting when equipment or machinery will likely fail using data collected by IoT sensors. Businesses use real-time data to monitor equipment performance and make informed decisions rather than relying on a fixed maintenance schedule or waiting for a breakdown to happen. How does IoT predictive maintenance work? IoT predictive maintenance takes a future-focused approach to equipment care. It leverages the power of the Internet of Things (IoT) by placing tiny sensors directly on machines. These sensors act as silent observers, constantly monitoring key metrics like vibration, temperature, and energy consumption.

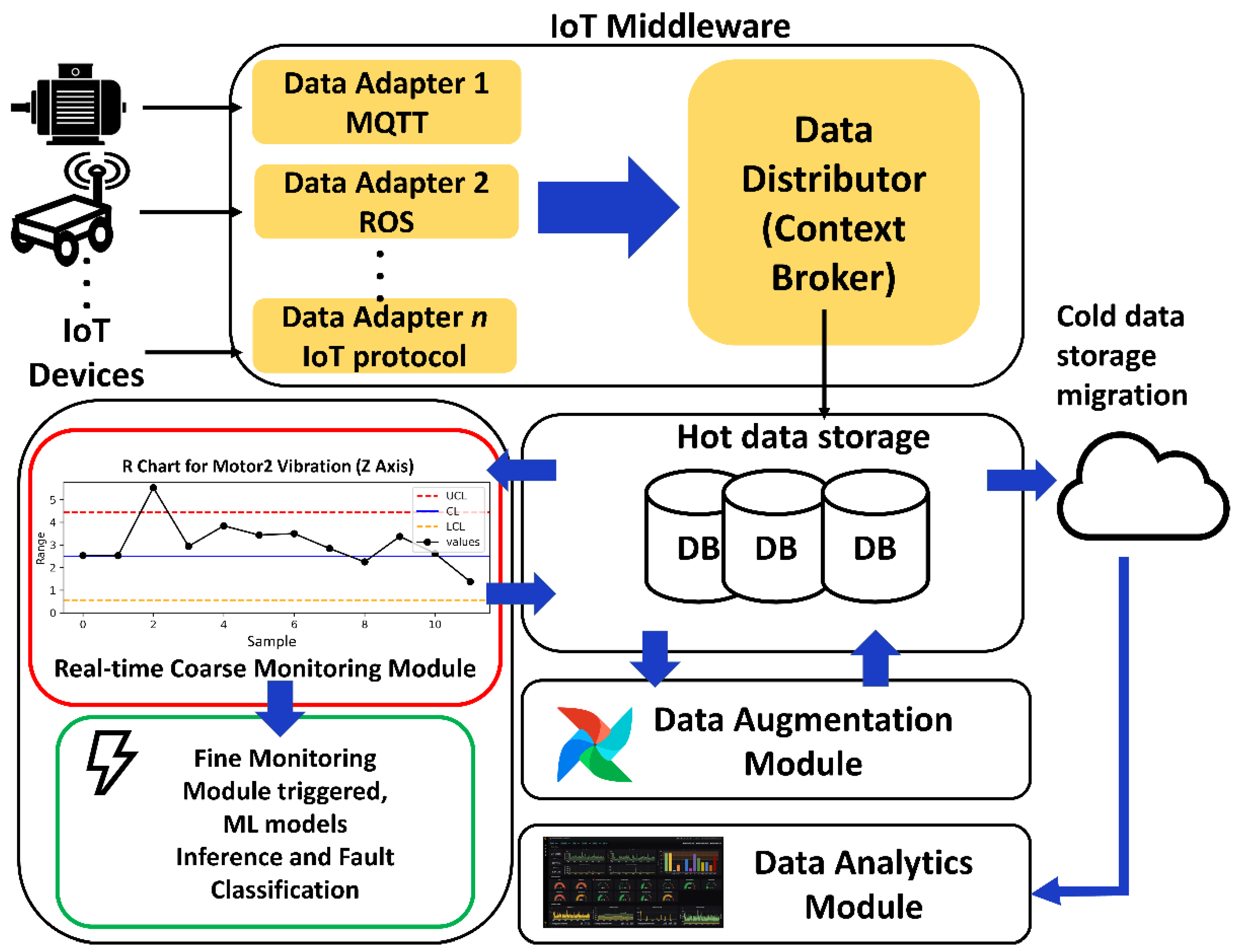

Moreover, an analysis of predictive maintenance techniques, processes and tools in manufacturing systems and an integrated predictive maintenance framework is proposed in [20]. That framework is composed of three components, namely data collection and analysis, information management and a dashboard for sustainability maintenance.

The Power of IoT Predictive Maintenance: A Step Circuit Diagram

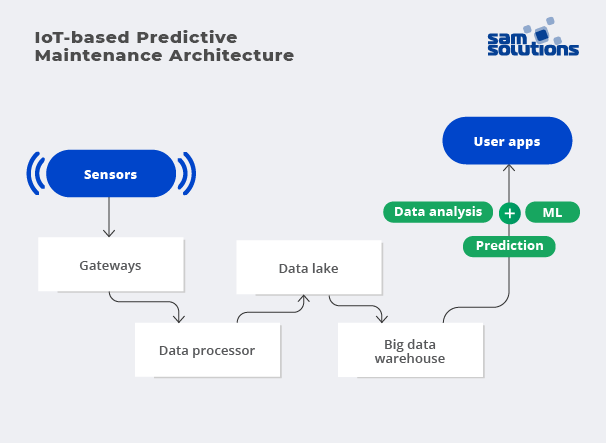

The system design adopts hierarchical architecture, including data acquisition layer, data transmission layer, data processing layer and application layer. By monitoring the running state of electrical and electronic equipment in real time, the system can predict the equipment failure and take corresponding maintenance measures, thus prolonging

Essentials of the Predictive Maintenance Function. The operation of maintenance systems is based on such latest IT trends as fog computing, big data, AI and ML, deep learning, and cloud computing. IT specialists design IoT platforms adjusted to the needs of the specific projects. They equip systems with necessary devices and ensure stable data

How to Build a Predictive Maintenance System Using IoT Circuit Diagram

Similarly, General Electric (GE) applies IoT-based predictive maintenance to monitor jet engines, preventing costly failures mid-flight. 🔹 Step 2: Deploy IoT Sensors for Data Collection IoT-enabled predictive maintenance relies on smart sensors to continuously collect machine health data.